If carefully selected, plastic is an essential material used for faucet components – to ensure water safety and to provide hard-wearing and long-lasting fixtures.

Plastic is an essential component for faucets to be safe, durable and long-lasting.

There are varying ways plastic is used in faucets and it is often perceived as less durable or less suitable for high-quality products. However, this is not always correct. Depending on the manufacturer and the specific type of plastic used, it comes in multiple forms, functions and qualities. Here’s all you need to know.

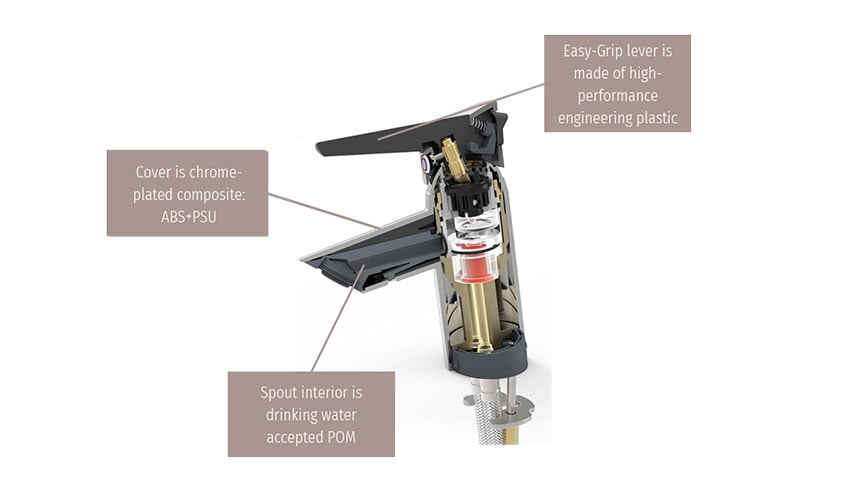

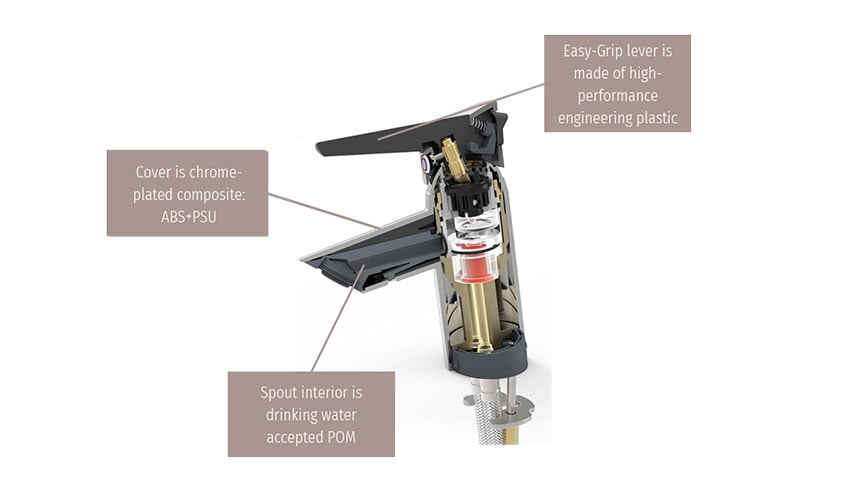

In Oras faucet applications, composite and hard-wearing plastics can be the optimal solution and are indispensable to deliver high performance and durability. Depending on the type and properties of the plastic used, plastic covers a wide range of applications in faucets.

Plastic can be used for:

- The outer body and handles

- The cartridge and valves

- Spout interior

- The aerator

- Pipes and connections

- Etc.

So what’s the difference and which type of plastic is used for which part of the faucet? Here are the kinds of plastics that you should know about.

Composite material

Composite material combines two or more separate materials and can be used in covers, spouts, bodies, levers and battery cases.

These include reinforced plastics, such as glass fibre and polymer or ABS composite, such as ABS engineering plastic-chrome combinations.

Composite plastics can also be moulded on to various components, in the form of plastic-plastic, plastic-metal or plastic-rubber combinations.

Combined with PSU (Polysulfone) engineering plastic, for example, the composite structure is often used in medical technology as it’s physiological inert and extremely durable in high temperatures.

Composite is a strong and durable, yet also light material, which is why it widely used in industries such as medical, aerospace and automotive.

ABS engineering plastic

ABS engineering plastic components are widely used in products such as laptops and mobile phones. It is a strong and durable material, which offers good resistance to high and low temperatures and chemicals. As plastic does not heat up the same way as metal does when in contact with hot water, it is a perfect material to be used in faucet levers, outer bodies and covers, handles and shower heads. Additional benefit of ABS is that it can be chrome-plated, which makes it an easy-to-process material.

ABS engineering plastic is commonly used for faucet levers due to its excellent resistance to high and low temperatures.

PSU/PPSU engineering plastic

Because of its excellent chemical properties, PSU is also suitable for high-performance applications, such as bearings, precision gears and thermostatic cartridges as well as for lever interfaces due to its easy-grip material.

At Oras, PSU engineering plastic is commonly used in thermostatic cartridges.

It is a safe material to be used with parts in contact with food, even in high temperatures.

At Oras, PSU is for example in thermostatic cartridges and in the easy-grip levers of Oras Optima kitchen and washbasin faucets.

POM engineering plastic

Known as acetal, or polyacetal, POM engineering plastic is used for components that require stiffness, low friction and high dimensional stability. This kind of plastic is solvent, fuel-resistant and a particularly durable choice for components with water contact, such as the spout’s interior.

Examples of faucet parts that use POM engineering plastic.

Why plastic?

Now that you have an idea of the different kinds of plastics used, let’s summarise why manufacturers choose plastic to build certain faucet components:

- Plastic is a strong and durable material, ensuring that the components last for a long time

- Plastic can resist different temperatures without getting damaged, meaning that cold and hot water can flow without affecting the plastic components. If used for outer bodies, and as the surface does not heat-up, the function can remarkably reduce the risk of scalding, particularly useful to avoid exposure to hot water pipes or shower faucets

- Plastic doesn’t affect the quality of drinking water and doesn’t contaminate it with harmful chemicals and microbes, which is why it is often used for the spout’s interior

- Plastic is 100 % corrosion-resistant (unlike certain types of metals, which naturally react to their environment and gradually wear out over time)

- Plastic resists humidity, which is important when water is involved (to avoid mould, for instance)

- And, finally, plastic is a lightweight material and doesn’t add unnecessary weight to the faucet, making it easier for installers to carry around and set up

Composite materials used in Oras Optima single-lever faucet.

Not all plastic is necessarily a sign of low quality. The careful selection of the right plastic properties, can ensure that your faucet is hard-wearing, resists different temperatures, and stands up to corrosion. Make sure to pay attention to the material and the quality of the plastic that is used and consult your installers or manufacturers to learn more about its properties. This way, you can ensure durable and qualified components for your clients.